ETI-SD Modular Automation

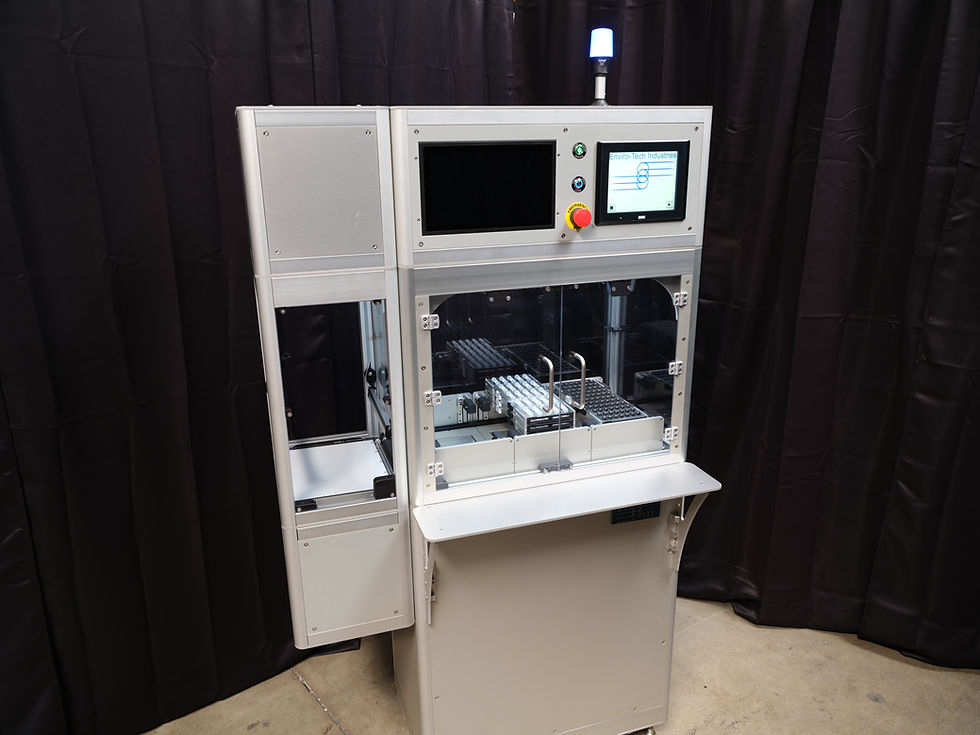

ETI-SD's compact modular automation systems are designed around a unified framework, facilitating compatibility and connectivity throughout the product line. They can often provide both standalone functionality, and expanded functionality/performance when combined with other ETI-SD modules. Some examples can be found below.

Our JEDEC-compatible Batch Processing Laser Module integrates Keyence MD-U and MD-X Lasers for high speed & high quality laser processing in an ultra compact footprint. ETI-SD's tray-handling automation enables hands-free operation with long walk-away times. Multiple Laser systems can be concatenated to increase throughput or add different lasers for products requiring multiple wavelengths. ETI-SD Loader/Stacker modules can be added for expanded capacity and longer walk-away times.

Our InkJet printing unit leverages VideoJet's High-Res (HR) printing units to achieve high quality dot-matrix printing on a variety of substrates. Job setup is quick and intuitive thanks to our intuitive software, facilitating text, graphics, and codes. Arrays of components can be marked via manual loading, and automated loading when combined with our Loader Stacker module.

The ETI-SD fiber laser module can accommodate manual part marking for low-volume and R&D settings, as well as automated batch-level marking when combined with our Loader Stacker module.

Our Loader Stacker module is at the core of batch-level processing. By leveraging ETI-SD customizable parts trays, many product geometries and sizes can be processed via connected automation modules. New trays can be created as product lines grow and evolve to ensure customers receive the best value and versatility from our modular automation. Trays can be serialized and rigorously tracked throughout the process workflow.

Our Automated Heat Sealer module enables batch-sealing of both standard and custom consumables. Sealing parameters can be defined via recipe for optimal temperature, pressure and timing settings for maximum versatility and tunability. This video showcases sealing of standard microtiter plates, however, the ETI-SD trays and sealing module can be quickly customized to handle new product types. Furthermore, this unit is fully compatible with other ETI-SD modules for added capabilities, including staging/warehousing, dispensing, part marking, and laser processing.

Smaller add-on modules can be connected for added capabilities, such as ultra-high resolution full-tray imaging at up to 400 megapixel resolution. This capability can be leveraged for both quality control, as well as high-detail archival imaging of all processed components.

This part handling module Integrates Yaskawa's MotoMini nimble 6 DOF robot, allowing automated part handling of complex shapes and geometries. Currently under development, this unit will facilitate the transfer of bulk-packaged components onto our custom parts trays for easy downstream batch-level processing.

© 2023 Enviro-Tech Industries